[fusion_builder_container hundred_percent=”no” hundred_percent_height=”no” hundred_percent_height_scroll=”no” hundred_percent_height_center_content=”yes” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” status=”published” publish_date=”” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” border_size=”” border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=””][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” last=”no”][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””]

What is nailing?

As noted in “geotechnics and soil improvement” section, nailing is one of the soil improvement methods. soil Nailing consists of steel rebar installation (nail), grouting and shotcrete construction.

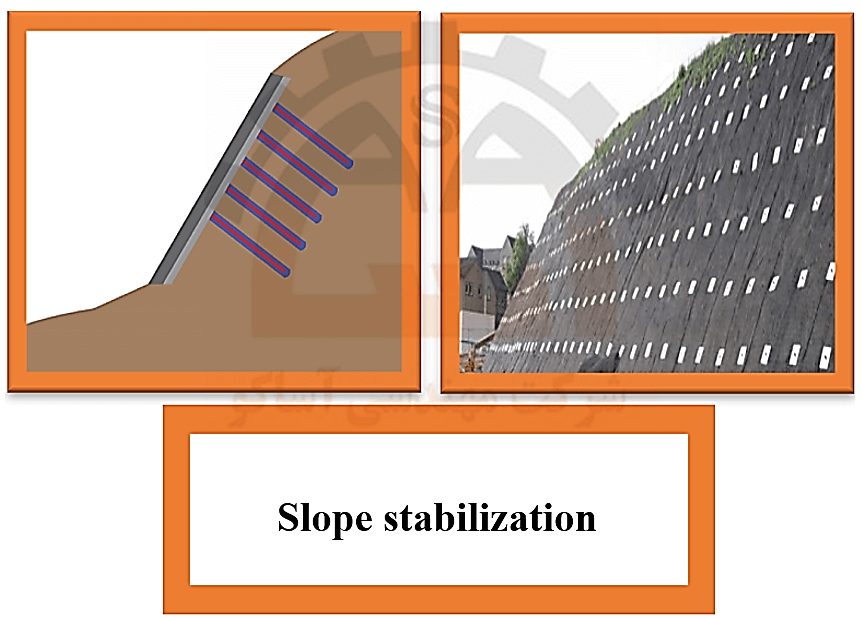

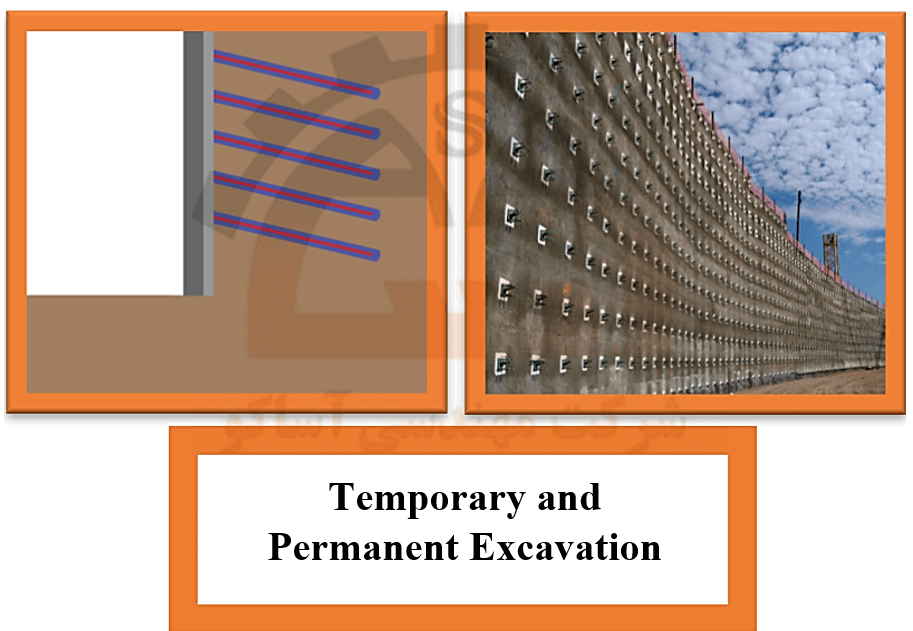

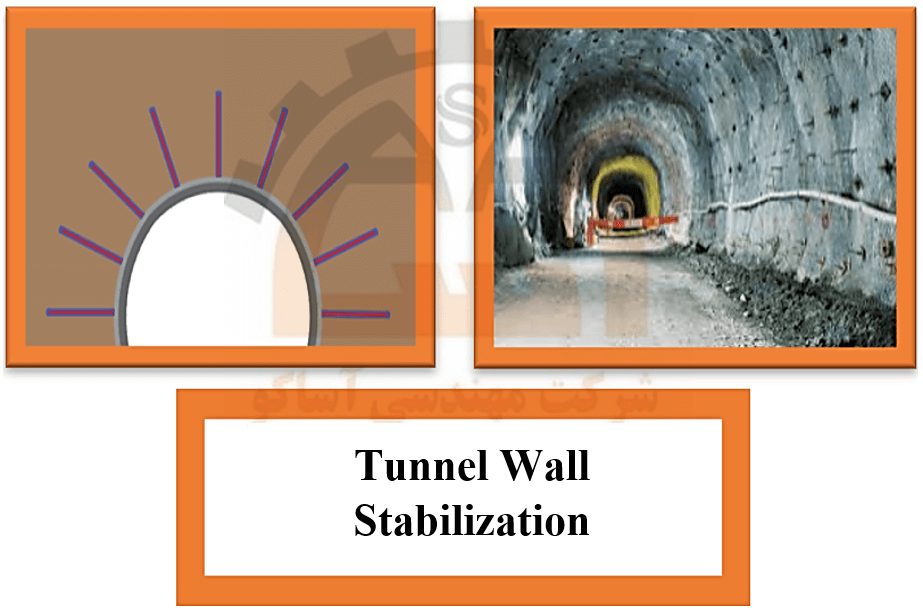

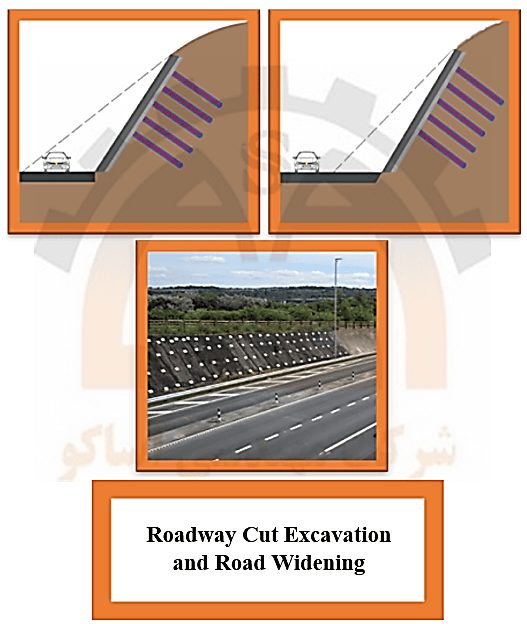

Soil nailing usually is used for stabilization of existing slopes, excavation walls, tunnel walls, roadway cut excavation, roadway widening and repair of existing retaining structures.

ASACO engineering company with excellent histories and successful experiences and also having specialized experts, is one of the best companies in the field of design and construction of nailing all over the country.

Nailing applications

Nailing walls are suitable for situations with vertical or near vertical excavation. In general, nailing is used in the following cases:

Nailing design method

Generally, in design of soil nail walls two limiting conditions must consider:

1-Strength Limit State

This limit state refers to failure or collapse modes in which the applied loads induce stresses greater than the strength of the whole system or individual components of system, and lead to instability of system. The design of nailing wall in soil must ensure that the system is safe against all failure modes below:

-external failure

-internal failure

-facing failure

2-Service Limit State

This limit state refers to conditions that disrupt the normal and safe performance of the structure and lead to excessive wall deformation, total or differential settlement, cracking of concrete facing and fatigue due to repetitive loading.

In principles of nailing design, drainage of soil behind wall and corrosion of nails or other metal components must be considered.

The main reference for design and construction of nailing is FHWA standard. Dear visitor, you can download the last version of this publication “here”.

Experts in ASACO, in order to design nailing system in different projects, in addition to utilize technical knowledge and control calculations manually, use different softwares such as PLAXIS, Geo Studio, FLAC 2D, FLAC3D, ABAQUS.

Construction sequence of Nailing

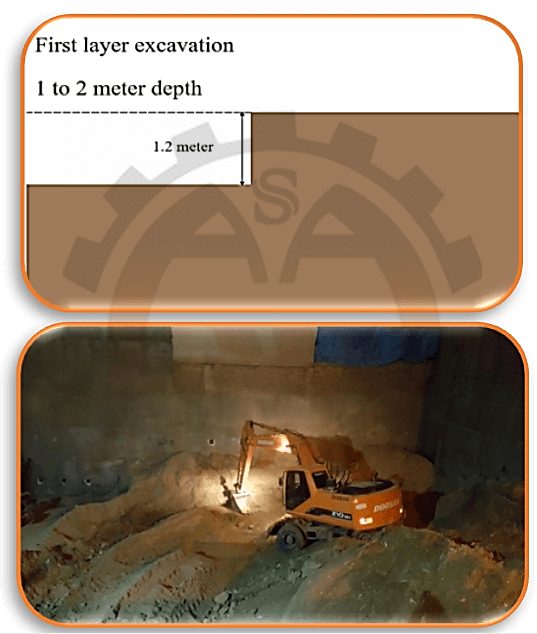

Excavation

The first stage in nailing construction is excavation. Primary excavation for the first layer is done to a depth which the excavated surface remains stable without any support for a short period of time (usually 24 or 48 hours). The width of excavated surface should be sufficient for equipment installation.

Drilling of nail holes

After excavation to desired depth and width, drilling of nail holes in considered length, diameter, inclination and horizontal spaces that has been achieved in design stage is done.

Installation of nails

In this stage, nails (rebars) are placed in drillholes. Nails are usually solid, but sometimes hollow nails are used too. Before placing the nails into drillholes, in order to adjustment and maintenance of nail in the center of drillhole and also, to ensure that a minimum thickness of grout completely covers the nail bar, centralizers should be installed into the hole. In some places that the risk of corrosion exists, for protecting materials against corrosion, special coatings are used for rebars.

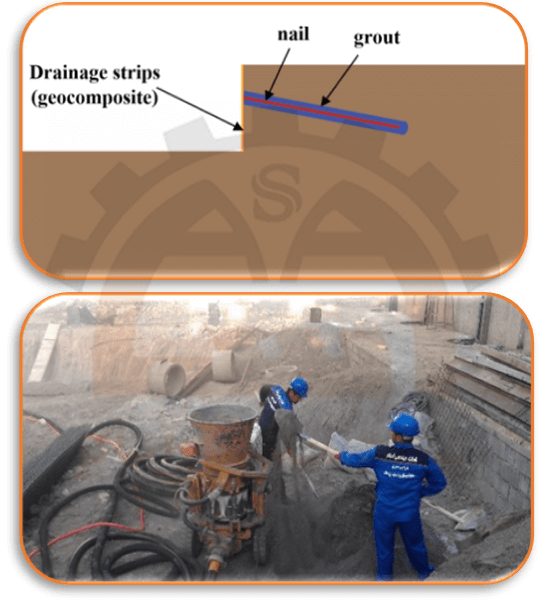

Grouting

After installation of rebars into drillholes, grouting should be done. For this purpose, the grout pipe is inserted into drillhole, and the cement is injected into the hole under gravity or by low pressure. When self-drilling bars are used, drilling and grouting are done in one step. After grouting, drainage strips (geocomposit) are installed between nails on the excavation face and extend to the bottom of the excavation to take out collected water from the pit.

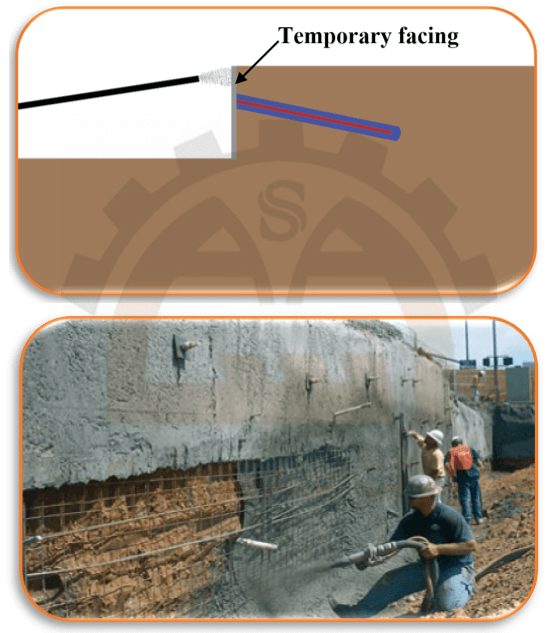

Temporary wall facing construction

Before excavation of next layer, in order to maintain the stability of excavation face and create continuity, a reinforced shotcrete layer with thickness of 75 to 100 millimeter is constructed on the surface. Welded wire mesh is commonly used for shotcrete reinforcement. In some situations, welded wire mesh is installed on the excavation face after before drilling of nail holes.

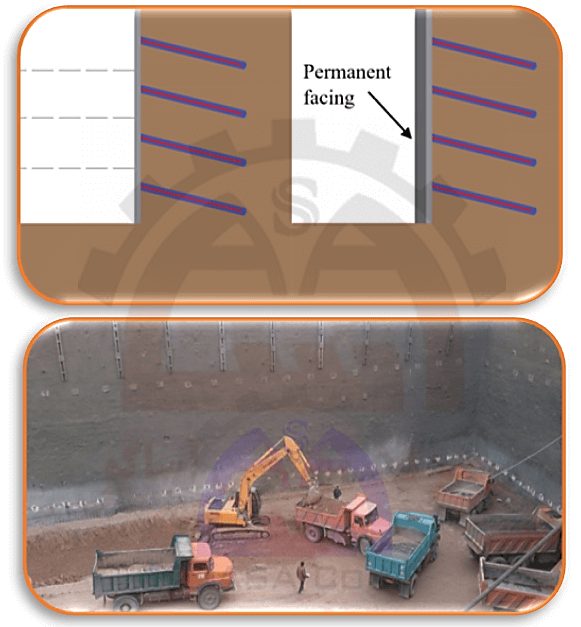

Permanent facing construction

After completing steps 1 to 5, the permanent facing should be constructed. The permanent facing depending on situation, may be reinforced shotcrete with welded wire mesh, in-situ reinforced concrete or precast panels.

ASACO engineering company is one of the most successful companies in the field of design and construction of nailing projects (temporary and permanent stabilization of excavations, slope stabilization, roadway widening, tunnel walls stabilization, ….) all over the country. in order to obtain more information about projects done by ASACO, you can click on “project” section to view the company histories in this field.

Loading test

One of the important stages in nailing projects construction, is in-situ loading test. In order to ensure that the design requirements are met, ie bearing the design load with a suitable safety factor by the soil, the nail wall is tested in the fields. Another reason for doing this test is, assurance of contractor accuracy in the construction of the soil nail wall.

Nailing cost

The cost of nailing construction is depending on many factors such as, ground condition, site accessibility, required dimensions for nailing construction, the type of permanent facing, corrosion protection, temporary or permanent application, availability of specialized contractors in soil nailing and shotcrete, regional conditions (seismicity, freezing, …). For example, in favorable soil conditions, nailing costs are reduced in comparison with other methods and in unfavorable conditions usage of nailing is not cost-effective. But in general, it can be said that the cost of nail wall construction is relatively lower compared to concrete weight walls and retaining walls in the ground.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]