[fusion_builder_container hundred_percent=”no” hundred_percent_height=”no” hundred_percent_height_scroll=”no” hundred_percent_height_center_content=”yes” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” status=”published” publish_date=”” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” border_size=”” border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=””][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” last=”no”][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=””]

As noted in soil improvement section, one of the soil improvement methods, in order to supply bearing capacity and stability, is deep soil mixing or in short DSM. The meaning of deep soil mixing is blending the soil with cementitious material such as cement, lime, bentonite, steel slag, fly ash, etc. to desired depth. Finally, mixture of soil with cementitious material becomes single or interconnected column. The improvement of soil with this method has become one of the most usable methods between new methods of soil improvement.

The amount of cementitious material in deep soil mixing method depends on initial moisture content of the soil around. The researches show that deep soil mixing lead to improvement of soil mechanical properties such as compression resistance, stiffness, elasticity modulus and consolidation behavior of soil.

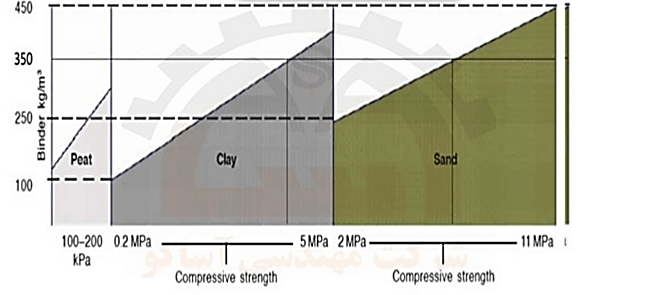

Compression resistance of improved soil by this method depends on different factors, such as soil type, amount of cementitious material, processing method, mixing time etc. in the picture below the amount of compression resistance according to the amount of cementitious material has estimated.

The design and construction of this method is according to simple principles but its performance depends on the quality of construction that this requires the contractor experience and also machinery and specific equipment.

ASACO with modern equipment and facilities is one of the pioneer companies in design and construction field of DSM method throughout the country.

Deep Soil mixing construction methods

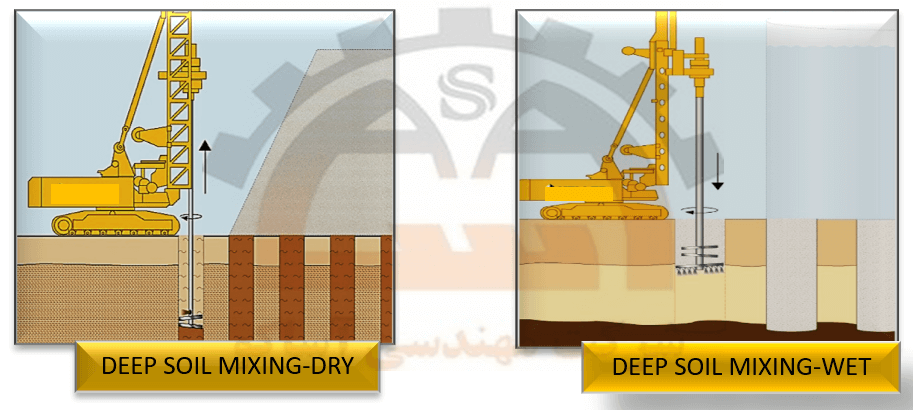

-Wet method

The additive cementitious material is combined with water in desired proportion and then the grout is mixed with soil to desired depth by special equipment.

-Dry method

In dry method the additive material is mixing with soil in dry form. This method is possible just in soils which have enough moisture for chemical reactions between adhesive particles, soil particles and underground water. The advantages of this method include the stabilization of very weak soils in deep sediments. The diameter of columns in this method varies between 60 to 80 centimeter and the depth could be over 25 meters.

The soils stabilized with DSM method, are formed in two forms of single and interconnected columns. Interconnected columns are used in order to sealing and insulation.

Also, in this method depending on soil improvement purpose, soil columns are placed in single, panel, block, stabilized network.

DSM method is mainly used in cohesive soils and due to difficulty of mixing, is not used in very hard soils. Deep soil mixing in wet method is applicable in fine-grained, coarse-grained and also organic soils and pits and in dry method is applicable in fine-grained, organic soils and pits.

necessary equipment

necessary equipment for this method includes constant or moving tank to keep and mix cementitious material, feeding machine and drilling rig and Also mixing tools includes single or multiple drilling rods with the drill at the end and horizontal blades along it.

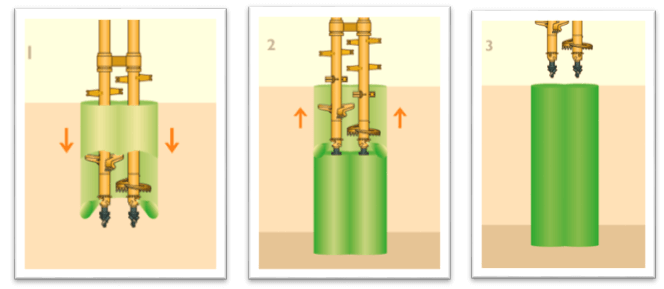

Deep soil mixing construction

In this method, a drilling rod is inserted into the soil and plunged to desired depth and after that, blades rotate in the opposite direction and move upwards. As the rod moves upwards, the grout or dry material is poured into the soil and mixed with the soil by horizontal blades. In this method, no vibration is created in the soil and adjacent structures.

The composition and volume of grout is different According to soil properties and also amount of required bearing and sealing. By adding different components to grout, its resistance parameter will change. For example, addition of bentonite to increase grout hardness and also addition of steel elements increases flexural capacity of DSM columns.

DSM applications

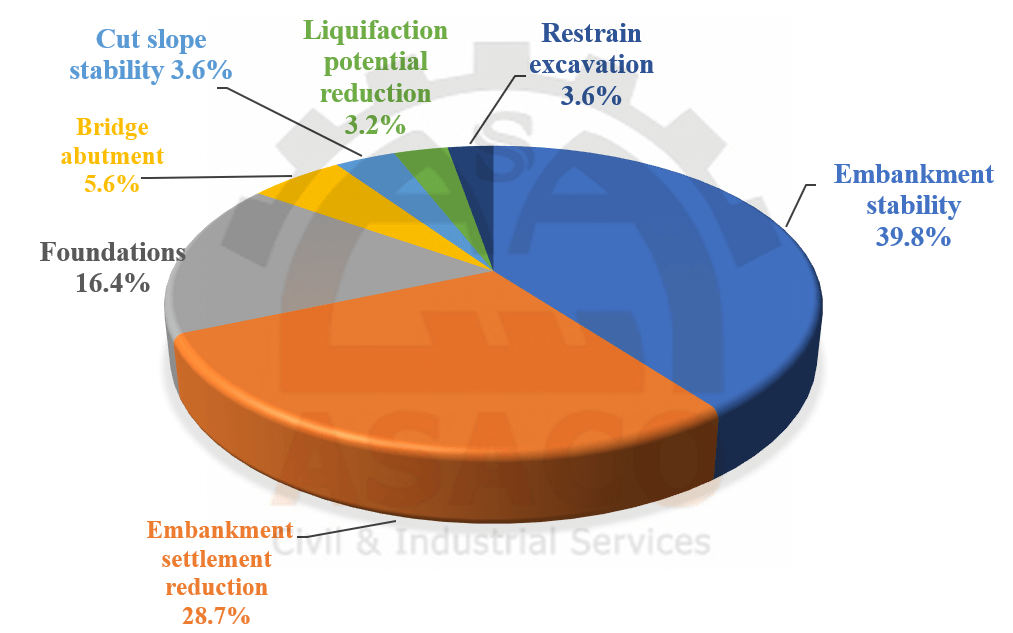

Deep soil mixing is one of the soil improvement methods that is compatible to environment similar to stone column method. The soil obtained by this method, has a higher resistance and density and lower permeability. In generall, applications of this method include the following:

-Embankment stability

-Reduce embankment settlement

-Foundations

-Restrain excavation

-Bridge abutment

-Reduce liquifaction potential

-Cut slope stability

According to researches, the amount of using this method in different applications is shown in the picture below:

Design Considerations in the DSM method

Deep soil mixing design includes evaluation and selection of improved soil parameters and also pattern and dimensions of columns. Expected compressive resistance of soil is usually selected according to physical and chemical properties of improved soil, groundwater conditions, type and amount of cement and other relevant charecteristics such as water to cement ratio.

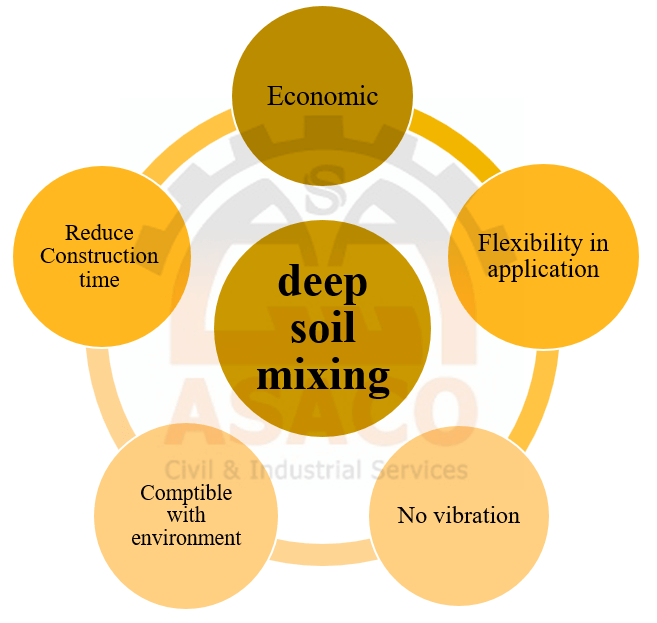

Deep soil mixing advantages

Soil improvement with this method, increase the soil quality and improve its mechanical and resistance parameters. This method is effective for reduction of liquefaction potential in seismic area. In general, advantages of this method are shown in the following:

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]